GWM NEW ENERGY

Hi4

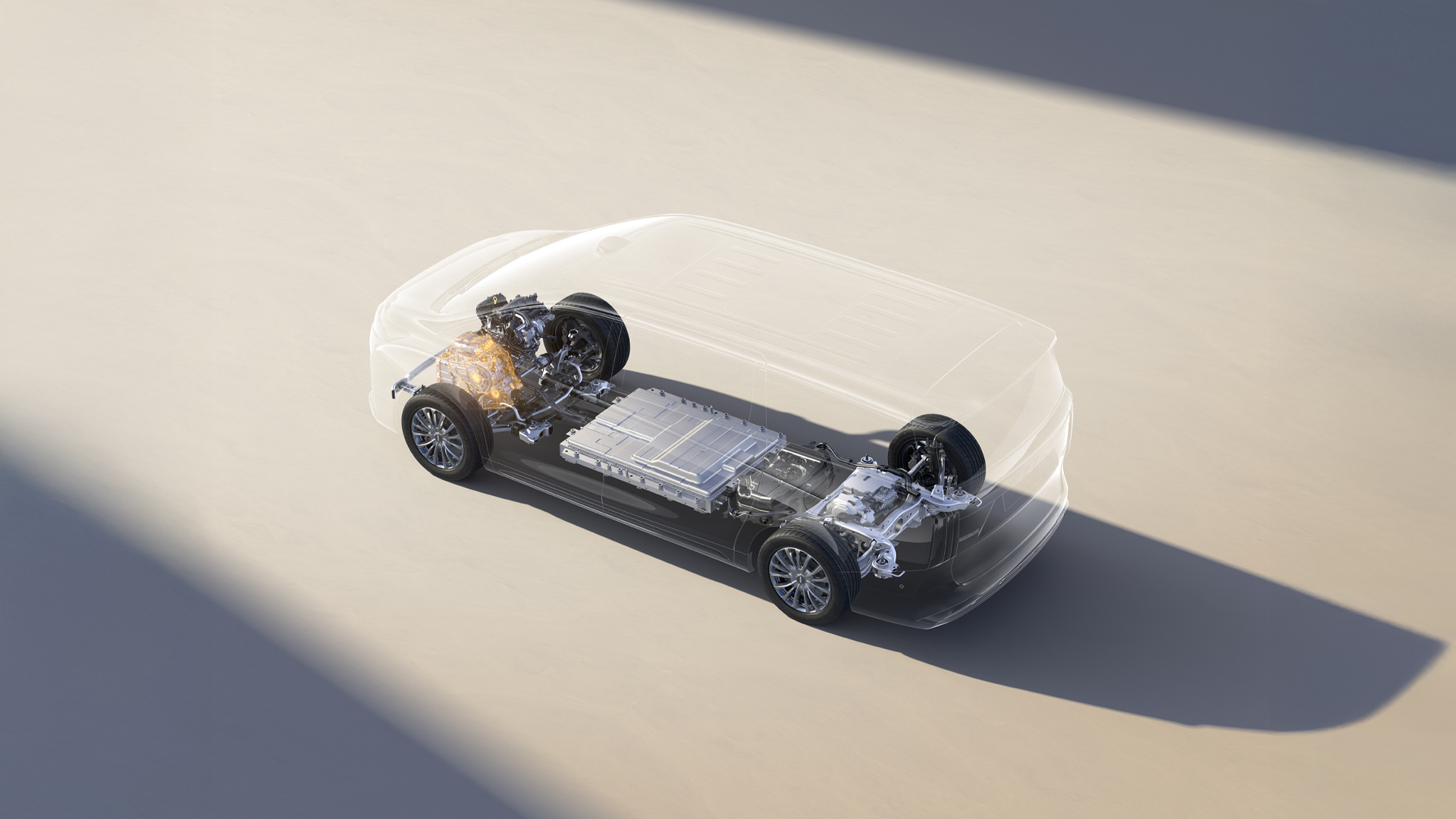

The new intelligent 4WD electric hybrid technology, Hi4 truly realizes "performance of four-wheel drive and the energy consumption of two-wheel drive", achieving "optimal efficiency in all working conditions, worry-free driving in all scenarios".

H(Hybrid)

i(Intelligent)

4(4WD)

Hi4, H (Hybrid) , I (Intelligent), 4 (4WD), the new hybrid architecture Hi4 represents the world's first intelligent control four-wheel drive hybrid technology. Based on the concept of "go with more", GWM uses the innovative configuration of dual-motor series-parallel electric four-wheel drive on the front and rear axles to create a "ceiling-level" hybrid technology.

The Hi4 achieves the "four-wheel drive experience, two-wheel drive price, four-wheel drive performance, two-wheel drive energy consumption" through the dynamic switching and intelligent energy management system of 3 engines and 9 modes, achieving "optimal efficiency in all operating conditions and worry-free driving in all scenarios".

Three Innovations

The new intelligent four-wheel drive hybrid technology Hi4 achieves three major innovations, namely, the hybrid "new configuration" with three power sources and dual-axis distribution, the "new breakthrough" of the iTVC intelligent torque vector control system, and the "new height" of the electromechanical coupling transmission system.

New Configuration

New Breakthrough

Hybrid dedicated engine

• Achieved optimal engineering thermal efficiency of 41.5% with the best current industry technology configuration

• 16:1 ultra-high compression ratio

• 350 bar high-pressure injection system

• 28% ultra-high EGR system

• 0.3 bar ultra-low friction

Hi4 front drive module assembly

• Multi-in-one highly integrated drive unit,two-speed electromechanical coupling unit

•Variable lubrication flow control, low friction bearings, application of low viscosity oil, highest transmission efficiency of up to 98%

•Low harmonic motor, high coincidence shaft teeth, quiet driving under all conditions

Hi4 rear drive module assembly

•150kW high-efficiency drive motor, motor's highest efficiency > 96.5%

•Hair-pin flat wire motor, low harmonic winding, rotor skewed pole and other industry-leading technologies

•Fully autonomous controller, adopting redundant design for active safety algorithms and multi-core control chip

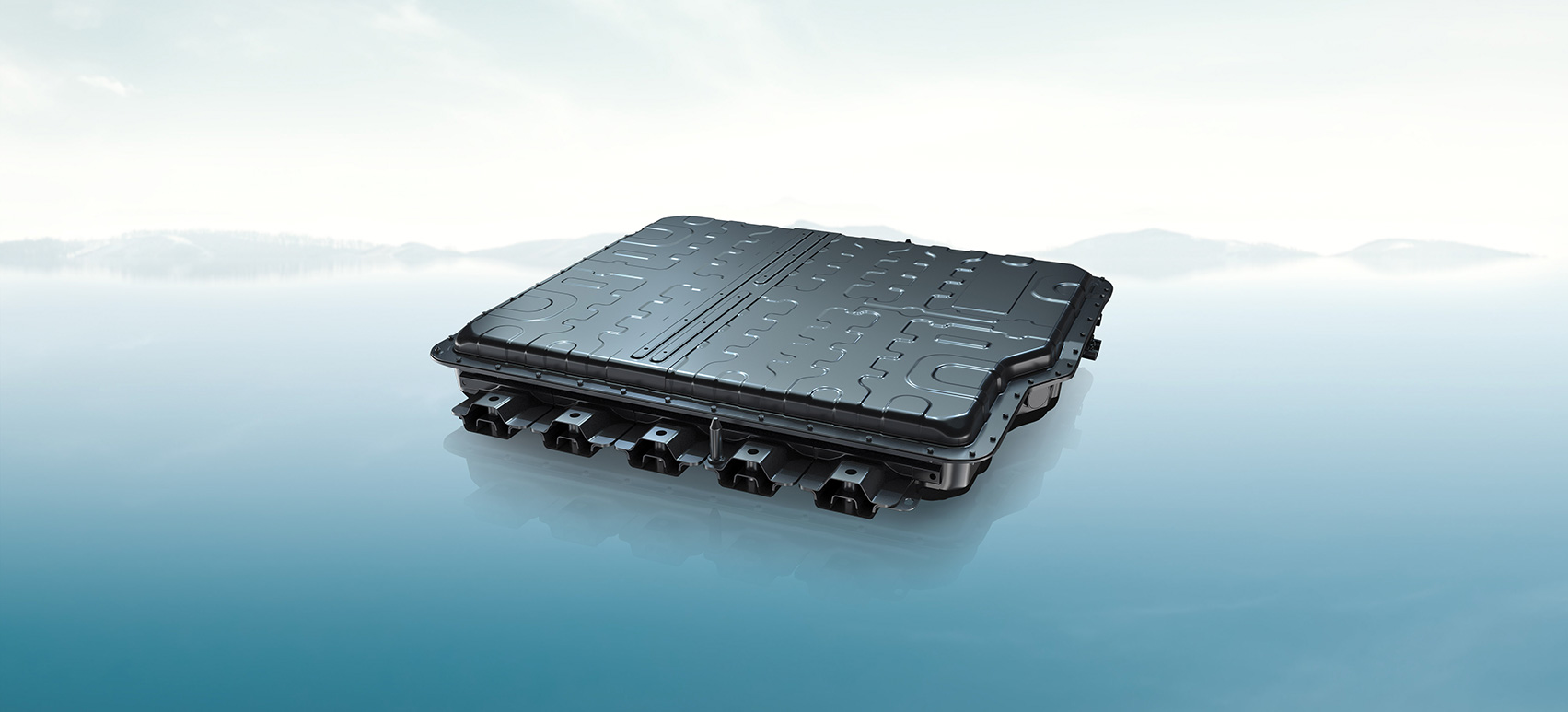

Good safety, high performance power battery

•Intrinsic safety redundancy design of battery cells, integration and protection of vehicle and pack, 24-hour cloud monitoring

•Adopting stacked low internal resistance design to achieve high-rate performance

I have read and accepted Privacy Policy *